UNIVERSAL

SUSPENSION

SYSTEM

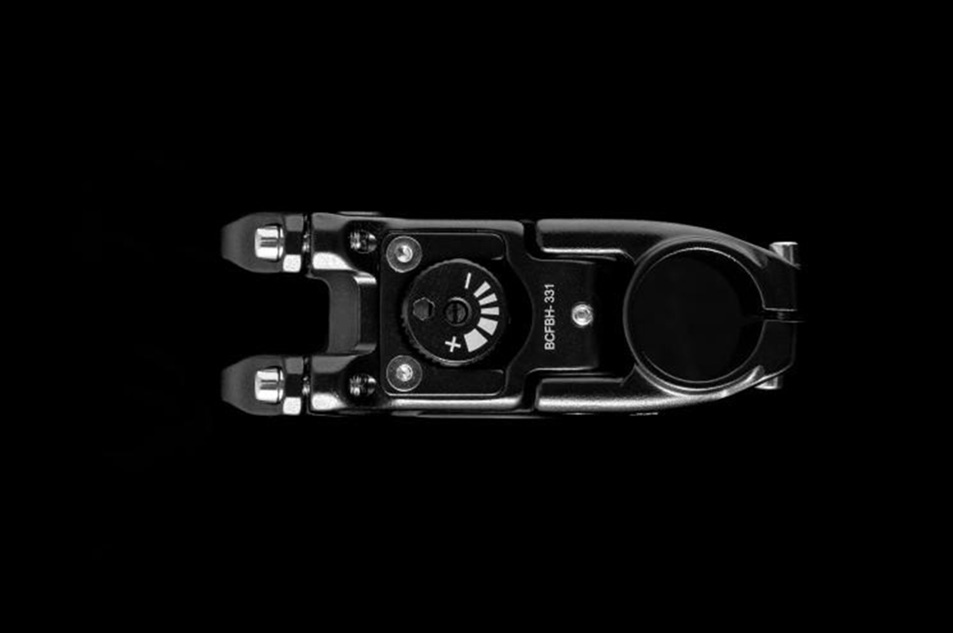

4-links structure with

HARD/SOFT micro adjustment function

The concept of USS design has been created from the traditional seat post, because after long term of riding, user’s lower body easily becomes numb.

USS makes the rider feels like flying an airplane to the clouds, and also feels as comfortable as riding a horse. The suspension function offers delicate downward and backward support, which is compatible with ergonomics of riding, and has been tested and confirmed in long term of riding test.

Research

Development

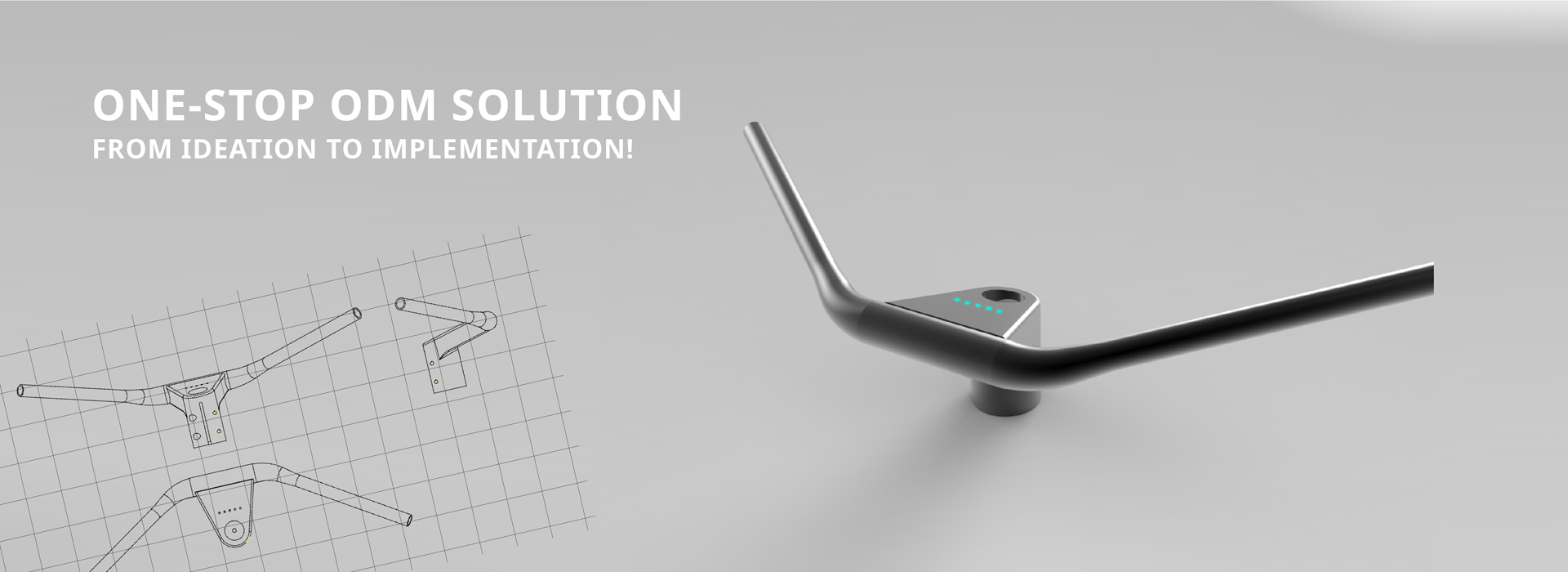

SAFORT established a research and development team in 2019 to design products according to customer needs, and gradually transformed into an ODM factory.

From scratch to appearance design, structural design, 3D printing, CNC proofing, laboratory testing to complete the final product.

-

Essential Bike Accessories Every Cyclist Needs!

Are you looking to take your cycling adventures to the next level? One of the best ways to do this is to add various accessories to your bike. Accessories not only make your ride more comfortable and enjoyable, but some of them are also essential for safety. In this blog post, we’ll discuss...read more -

Enhance Your Ride With the Right Handlebar and Stem

Cycling is one of the most popular forms of exercise and transportation in the world. Whether you’re a hardcore cyclist or someone who likes to ride around town on the weekends, there’s a wide variety of bike accessories that can improve your overall riding experience. This article wi...read more -

Ultimate Guide to Bike Accessories for Cycling Beginners

If you’re new to cycling, you might feel overwhelmed by the variety of bicycle accessories available on the market. From handlebars to seat posts, there are endless options to choose from. With so many products on the market, it’s easy to get lost in the sheer variety and end up buyin...read more